tea making process

Irrigation in Young Tea Area.

Sprinkler Irrigation System is used to spray water into the air and allowed to fall on the ground surface somewhat resembling rainfall to replenish water requirement.

Plucking in a Mature Tea Section

Tender shoots are constantly removed by plucking to produce Quality Tea.

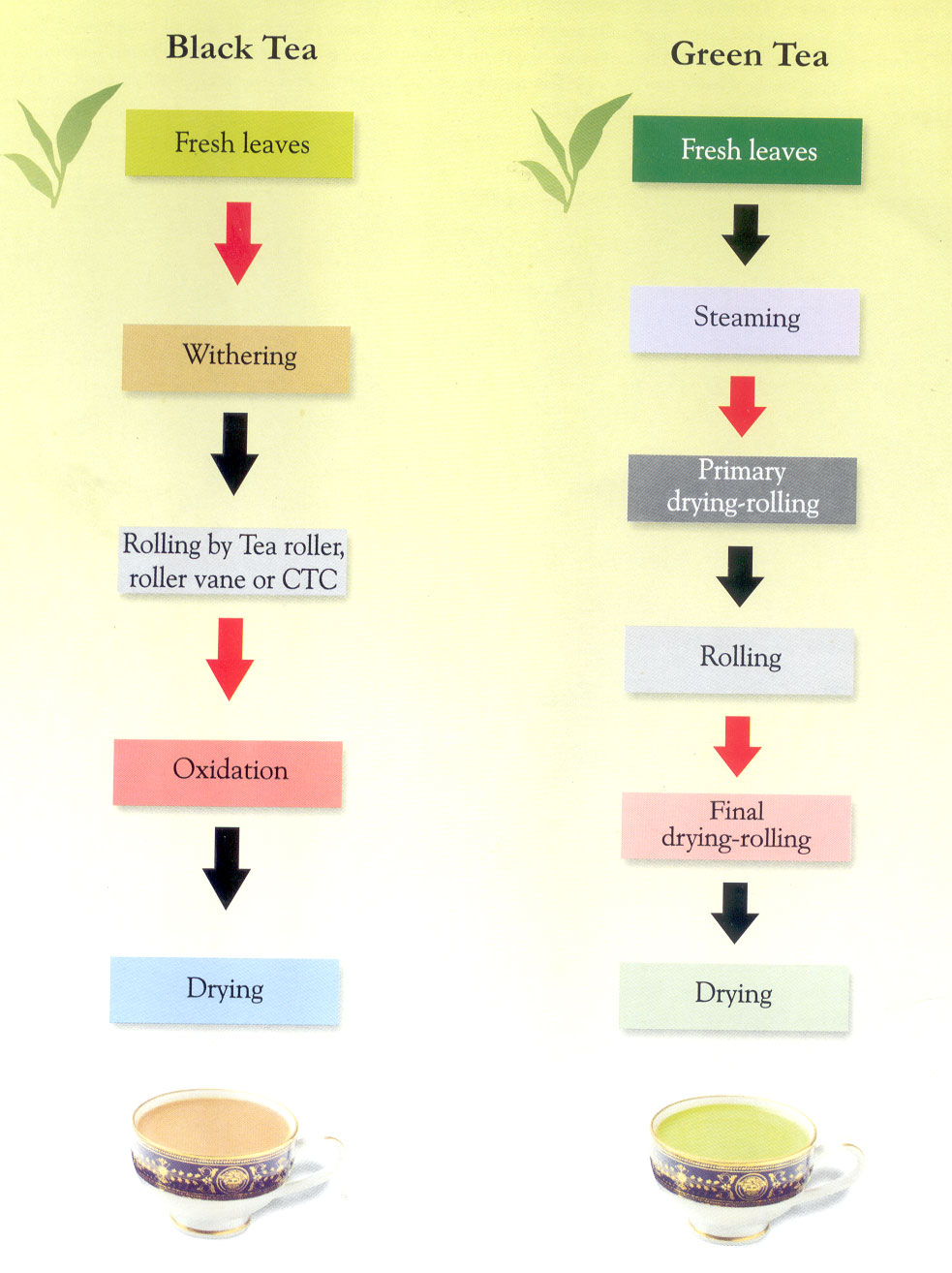

Process Involving Manufacture of Black Tea

Green Leaf is passed through several natural processing methods before it is converted into black tea.

Testing at the Garden Factory

Testing is done to evaluate cup qualities like brightness, briskness and pungency.

Process Involving Manufacture of Black Tea

| Process Steps | Main Objectives | Method | Machinery & Installation | Changes brought about |

|---|---|---|---|---|

| Withering | Partial dehydration of shoots (about 75 % moisture) to make them leathery for rolling: chemical changes | Exposure to air under natural or controlled conditions. | Withering lofts/ drums/ tunnels/ troughs: continous withering machine. | Lowering of moisture to about 55 percent; increases in caffeine, soluble sugars and amino acids; changes in proportion of organic acids and activity of leaf enzymes. |

| Rolling | Rapture and distortion of tea shoots to allow mixing of enzymes and substrates | Mechanical bruising, tearing, cutting, crushing, breaking and twisting | Crank Roller C.T.C Machines; Rotorvanc; Triturators; Barbora Leaf Conditioner; Continous Leaf Roller | Shoots cut and twisted; cellular constituents mixed; oxidative changes set in |

| Fermentation | Chemical changes of leaf constituents by enzymatic oxidation | Exposure ro air under controlled temperature (about 30 degree C) and humidity | Fermentaion floor/ tray/ trough/ drum; Continuous fermenter | Colour changes from green to coppery; polyphenolic bodies oxidised and condensed |

| Drying | Stoppage of fermentation; dehydration to ensure keeping quality of product | Exposure to blast of hot air in a counter current dryer (Inlet: 80 - 100 degree C Exhaust: 50-55 degree C) | Conventional Tea Dryer; Tocklai continuous dryer; Fluid bed dryer | Moisture reduced to about 4%. Product attains characteristics colour and appearance; some sugar is caramelised; polyphenols undergo epimerisation |

| Grading & Sorting | Remove dust and fibre & grading into 2 to 6 clean grades | The leaf is put through Grade Shifter. | Fibrex Pennvolt Sorting Machine | Sizing of different grades done. |